Small or complex parts are difficult to produce by casting or machining. Components that require sintering are often delicate, intricate, and easy to botch. Vacuum sintering is an efficient way to join parts with minimal waste.

Vacuum sintering produces consistent, bright parts with no seams, joints, or fillers.

Powdered metal, metal injection molding, 3D printing, and other similar technologies can benefit greatly from the superior quality and flexibility of vacuum sintering.

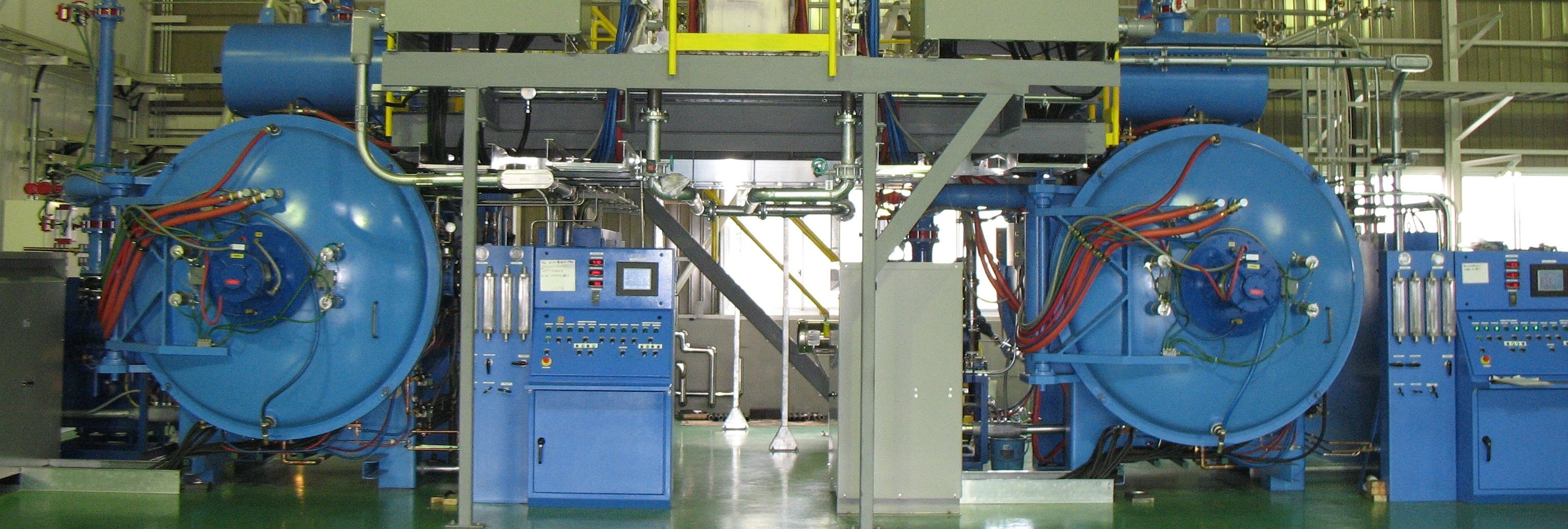

Benefits of a Vacuum Sintering Furnace

Much like heat treatment and brazing, vacuum sintering allows for more control over the quality of your parts, and a cleaner product post-sintering.

Vacuum sintering creates less waste and increases productivity since you don't need to worry about seams, joints, or fillers. In general, it's a highly efficient process that reduces (or eliminates) the need for secondary fabrications.

Here are just some of the benefits of vacuum sintering:

- Clean, bright parts

- Incredible design flexibility

- Quick turnaround

- Superior quality

- Fewer defects

- Easy maintenance

- Maximum productivity

How Vacuum Sintering Works

Debinding

All sintering starts with debinding.

The debinding process removes binder materials that can contaminate the furnace and the final product. Binding materials are originally necessary for each separate part compaction, but become unnecessary and undesirable during the sintering process.

Vacuum furnaces can be built to perform both debinding and sintering. Combining these processes in one furnace saves time and money. No part transfer, secondary machinery, or resources wasted on a repetitive process.

High Degree of Control

Vacuum furnaces are perfect for higher temperature sintering applications.

Vacuum sintering requires a high vacuum for clean, quality parts. You need to reach a very exact temperature to combine the metals, but not liquefy your part. Cooling speed is dependent on your material.

All of these factors are easy to control with the vacuum furnace's operating system. Highly customizable controls allow for manual or automatic temperature changes depending on the needs of your specific project. The temperature is uniform, ensuring consistent part quality across the board.

Temperature and pressure limits can be chosen during the engineering phase, and controlled manually or automatically during processing.